Imibhobho yentsimbi yeCarbon edibeneyo ejikelezayo yemibhobho yamanzi engaphantsi komhlaba

Uthungelwano lwamanzi angaphantsi komhlaba luyinxalenye ebalulekileyo yeziseko zophuhliso zesixeko okanye idolophu. Lunoxanduva lokubonelela ngamanzi okusela acocekileyo nakhuselekileyo kumakhaya, kumashishini nakwamanye amaziko. Ngaphandle kweenkqubo zombhobho ezithembekileyo, ukufikelela kumanzi acocekileyo kuya kuba semngciphekweni omkhulu, nto leyo enokubangela iingozi zempilo kunye nokuphazamiseka kobomi bemihla ngemihla. Ke ngoko, kubalulekile ukuqinisekisa ukuba izixhobo ezisetyenziswa kule mibhobho zikumgangatho ophezulu kwaye ziyakwazi ukuhlangabezana neemfuno zothutho lwamanzi angaphantsi komhlaba.

| Ububanzi obungaphandle obuchaziweyo (D) | Ubukhulu bodonga obuchaziweyo nge-mm | Uxinzelelo oluncinci lovavanyo (Mpa) | ||||||||||

| Ibanga lentsimbi | ||||||||||||

| in | mm | L210(A) | L245(B) | L290(X42) | L320(X46) | L360(X52) | L390(X56) | L415(X60) | L450(X65) | L485(X70) | L555(X80) | |

| 8-5/8 | 219.1 | 5.0 | 5.8 | 6.7 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 |

| 7.0 | 8.1 | 9.4 | 13.9 | 15.3 | 17.3 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 11.5 | 13.4 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 9-5/8 | 244.5 | 5.0 | 5.2 | 6.0 | 10.1 | 11.1 | 12.5 | 13.6 | 14.4 | 15.6 | 16.9 | 19.3 |

| 7.0 | 7.2 | 8.4 | 14.1 | 15.6 | 17.5 | 19.0 | 20.2 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 10.3 | 12.0 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 10-3/4 | 273.1 | 5.0 | 4.6 | 5.4 | 9.0 | 10.1 | 11.2 | 12.1 | 12.9 | 14.0 | 15.1 | 17.3 |

| 7.0 | 6.5 | 7.5 | 12.6 | 13.9 | 15.7 | 17.0 | 18.1 | 19.6 | 20.7 | 20.7 | ||

| 10.0 | 9.2 | 10.8 | 18.1 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 12-3/4 | 323.9 | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.6 |

| 7.0 | 5.5 | 6.5 | 10.7 | 11.8 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.4 | ||

| 10.0 | 7.8 | 9.1 | 15.2 | 16.8 | 18.9 | 20.5 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (325.0) | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.5 | |

| 7.0 | 5.4 | 6.3 | 10.6 | 11.7 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.3 | ||

| 10.0 | 7.8 | 9.0 | 15.2 | 16.7 | 18.8 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 13-3/8 | 339.7 | 5.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.1 | 13.9 |

| 8.0 | 5.9 | 6.9 | 11.6 | 12.8 | 14.4 | 15.6 | 16.6 | 18.0 | 19.4 | 20.7 | ||

| 12.0 | 8.9 | 10.4 | 17.4 | 19.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 14 | 355.6 | 6.0 | 4.3 | 5.0 | 8.3 | 9.2 | 10.3 | 11.2 | 11.9 | 12.9 | 13.9 | 15.9 |

| 8.0 | 5.7 | 6.6 | 11.1 | 12.2 | 13.8 | 14.9 | 15.9 | 17.2 | 18.6 | 20.7 | ||

| 12.0 | 8.5 | 9.9 | 16.6 | 18.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (377.0) | 6.0 | 4.0 | 4.7 | 7.8 | 8.6 | 9.7 | 10.6 | 11.2 | 12.2 | 13.1 | 15.0 | |

| 8.0 | 5.3 | 6.2 | 10.5 | 11.5 | 13.0 | 14.1 | 15.0 | 16.2 | 17.5 | 20.0 | ||

| 12.0 | 8.0 | 9.4 | 15.7 | 17.3 | 19.5 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 16 | 406.4 | 6.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.2 | 13.9 |

| 8.0 | 5.0 | 5.8 | 9.7 | 10.7 | 12.0 | 13.1 | 13.9 | 15.1 | 16.2 | 18.6 | ||

| 12.0 | 7.4 | 8.7 | 14.6 | 16.1 | 18.1 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (426.0) | 6.0 | 3.5 | 4.1 | 6.9 | 7.7 | 8.6 | 9.3 | 9.9 | 10.8 | 11.6 | 13.3 | |

| 8.0 | 4.7 | 5.5 | 9.3 | 10.2 | 11.5 | 12.5 | 13.2 | 14.4 | 15.5 | 17.7 | ||

| 12.0 | 7.1 | 8.3 | 13.9 | 15.3 | 17.2 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 18 | 457.0 | 6.0 | 3.3 | 3.9 | 6.5 | 7.1 | 8.0 | 8.7 | 9.3 | 10.0 | 10.8 | 12.4 |

| 8.0 | 4.4 | 5.1 | 8.6 | 9.5 | 10.7 | 11.6 | 12.4 | 13.4 | 14.4 | 16.5 | ||

| 12.0 | 6.6 | 7.7 | 12.9 | 14.3 | 16.1 | 17.4 | 18.5 | 20.1 | 20.7 | 20.7 | ||

| 20 | 508.0 | 6.0 | 3.0 | 3.5 | 6.2 | 6.8 | 7.7 | 8.3 | 8.8 | 9.6 | 10.3 | 11.8 |

| 8.0 | 4.0 | 4.6 | 8.2 | 9.1 | 10.2 | 11.1 | 11.8 | 12.8 | 13.7 | 15.7 | ||

| 12.0 | 6.0 | 6.9 | 12.3 | 13.6 | 15.3 | 16.6 | 17.6 | 19.1 | 20.6 | 20.7 | ||

| 16.0 | 7.9 | 9.3 | 16.4 | 18.1 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (529.0) | 6.0 | 2.9 | 3.3 | 5.9 | 6.5 | 7.3 | 8.0 | 8.5 | 9.2 | 9.9 | 11.3 | |

| 9.0 | 4.3 | 5.0 | 8.9 | 9.8 | 11.0 | 11.9 | 12.7 | 13.8 | 14.9 | 17.0 | ||

| 12.0 | 5.7 | 6.7 | 11.8 | 13.1 | 14.7 | 15.9 | 16.9 | 18.4 | 19.8 | 20.7 | ||

| 14.0 | 6.7 | 7.8 | 13.8 | 15.2 | 17.1 | 18.6 | 19.8 | 20.7 | 20.7 | 20.7 | ||

| 16.0 | 7.6 | 8.9 | 15.8 | 17.4 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22 | 559.0 | 6.0 | 2.7 | 3.2 | 5.6 | 6.2 | 7.0 | 7.5 | 8.0 | 8.7 | 9.4 | 10.7 |

| 9.0 | 4.1 | 4.7 | 8.4 | 9.3 | 10.4 | 11.3 | 12.0 | 13.0 | 14.1 | 16.1 | ||

| 12.0 | 5.4 | 6.3 | 11.2 | 12.4 | 13.9 | 15.1 | 16.0 | 17.4 | 18.7 | 20.7 | ||

| 14.0 | 6.3 | 7.4 | 13.1 | 14.4 | 16.2 | 17.6 | 18.7 | 20.3 | 20.7 | 20.7 | ||

| 19.1 | 8.6 | 10.0 | 17.8 | 19.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22.2 | 10.0 | 11.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 24 | 610.0 | 6.0 | 2.5 | 2.9 | 5.1 | 5.7 | 6.4 | 6.9 | 7.3 | 8.0 | 8.6 | 9.8 |

| 9.0 | 3.7 | 4.3 | 7.7 | 8.5 | 9.6 | 10.4 | 11.0 | 12.0 | 12.9 | 14.7 | ||

| 12.0 | 5.0 | 5.8 | 10.3 | 11.3 | 12.7 | 13.8 | 14.7 | 15.9 | 17.2 | 19.7 | ||

| 14.0 | 5.8 | 6.8 | 12.0 | 13.2 | 14.9 | 16.1 | 17.1 | 18.6 | 20.0 | 20.7 | ||

| 19.1 | 7.9 | 9.1 | 16.3 | 17.9 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.5 | 12.0 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (630.0) | 6.0 | 2.4 | 2.8 | 5.0 | 5.5 | 6.2 | 6.7 | 7.1 | 7.7 | 8.3 | 9.5 | |

| 9.0 | 3.6 | 4.2 | 7.5 | 8.2 | 9.3 | 10.0 | 10.7 | 11.6 | 12.5 | 14.3 | ||

| 12.0 | 4.8 | 5.6 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 | ||

| 16.0 | 6.4 | 7.5 | 13.3 | 14.6 | 16.5 | 17.8 | 19.0 | 20.6 | 20.7 | 20.7 | ||

| 19.1 | 7.6 | 8.9 | 15.8 | 17.5 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.2 | 11.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

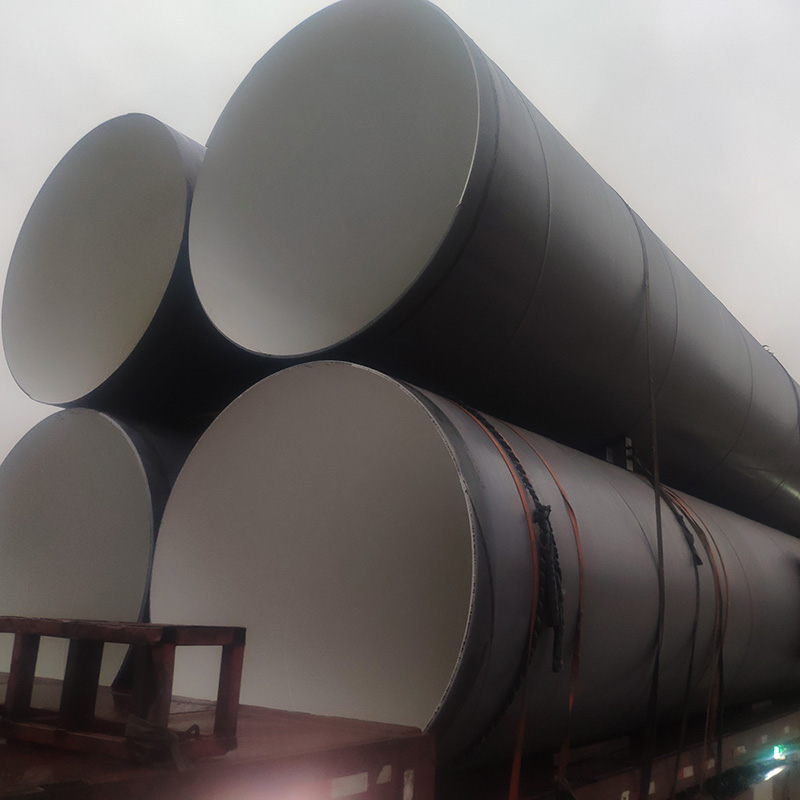

Umbhobho wentsimbi yekhabhoni edityanisiweyo nge-Spiral, efana ne-S235 JR kunye ne-S235 JRUmbhobho womgca we-X70 SSAW, lukhetho oludumileyo kwiipayipi zamanzi ezingaphantsi komhlaba ngenxa yokuqina kwayo okuhle kunye nokumelana nokugqwala. Iipayipi zenziwe kusetyenziswa inkqubo yokuwelda ejikelezayo, ukuqinisekisa ukuba ziqinile kwaye zinesakhiwo esikwaziyo ukumelana noxinzelelo kunye nezinto ezingqongileyo ezinxulumene nokuthuthwa kwamanzi angaphantsi komhlaba. Ukongeza, ezi pipes zakhiwe ngentsimbi yekhabhoni esemgangathweni ophezulu ukuze zibe namandla angcono kwaye zihlale ixesha elide, nto leyo eyenza ukuba zibe lukhetho oluthembekileyo kwiinkqubo zokusasaza amanzi ixesha elide.

Enye yezona nzuzo ziphambili zokusebenzisaimibhobho yentsimbi yekhabhoni edityanisiweyo ejikelezayoUkuthuthwa kwamanzi angaphantsi komhlaba kukumelana kwawo nokugqwala okuphezulu. Imibhobho engaphantsi komhlaba ihlala ivezwa kumswakama kunye nezinye izinto ezingqongileyo, ezinokubangela ukuba izinto zemveli ezifana nekhonkrithi okanye i-PVC zigqwale kwaye zonakale. Nangona kunjalo, imibhobho yentsimbi yekhabhoni imelana kakhulu nokugqwala, iqinisekisa ukuba igcina ukuqina kwesakhiwo sayo ngokuhamba kwexesha. Oku kuxhathisa ukugqwala kunciphisa kakhulu isidingo sokugcinwa nokutshintshwa, ekugqibeleni konga iindleko zenkqubo yamanzi.

Ukongeza, amandla kunye nokuqina kombhobho wentsimbi yekhabhoni odibeneyo ojikelezayo kwenza ukuba ube yindawo efanelekileyo yokufakelwa phantsi komhlaba. Le mibhobho iyakwazi ukumelana noxinzelelo lwangaphandle oluvela kumhlaba nakwezinye izinto ezingaphantsi komhlaba, iqinisekisa ukuba ihlala iqinile kwaye isebenza ubomi bayo bonke. Ukongeza, ukwakhiwa kwayo kunye nemiphezulu yangaphakathi egudileyo kunciphisa umngcipheko wokuvaleka okanye ukuvuza, okwandisa ngakumbi ukuthembeka nokusebenza kakuhle kothutho lwamanzi angaphantsi komhlaba.

Isishwankathelo,imibhobho yamanzi engaphantsi komhlabaziyinxalenye ebalulekileyo yeziseko zophuhliso zanamhlanje, kwaye ukukhethwa kwezinto ezisetyenziswa kwezi mibhobho kubaluleke kakhulu ekusebenzeni kwayo nasekuhlaleni ixesha elide. Imibhobho yentsimbi yekhabhoni edityanisiweyo nge-Spiral welded, efana nombhobho womgca we-S235 JR kunye ne-X70 SSAW, inika izibonelelo ezininzi zokuthutha amanzi angaphantsi komhlaba, kubandakanya ukuqina okuphezulu, ukumelana nokugqwala kunye namandla aphezulu. Ngokusebenzisa le mibhobho ikumgangatho ophezulu, iinkqubo zamanzi zinokuqinisekisa ukuhanjiswa kwamanzi okuthembekileyo nokufanelekileyo kuluntu ngelixa kunciphisa isidingo sokugcinwa nokutshintshwa.