Imibhobho yeSpiral eWelded Carbon Steel yeMibhobho yamanzi angaphantsi komhlaba

Uthungelwano lwamanzi aphantsi komhlaba luyinxalenye ebalulekileyo yaso nasiphi na isiseko sesixeko okanye idolophu.Linoxanduva lokubonelela ngamanzi okusela acocekileyo nakhuselekileyo kumakhaya, amashishini nakwamanye amaziko.Ngaphandle kweenkqubo ezithembekileyo zemibhobho yamanzi, ukufikelela kumanzi acocekileyo kuya kuphazamiseka kakhulu, okukhokelela kwiingozi zempilo ezinokuthi zibe nokuphazamiseka kubomi bemihla ngemihla.Ngoko ke, kubalulekile ukuqinisekisa ukuba izinto ezisetyenziswa kule mibhobho zikumgangatho ophezulu kwaye ziyakwazi ukuhlangabezana neemfuno zokuthuthwa kwamanzi aphantsi komhlaba.

| Idayamitha yangaphandle ecacisiweyo (D) | Ubungqingqwa boDonga obucacisiweyo kwi-mm | Ubuncinci boxinzelelo lovavanyo (Mpa) | ||||||||||

| IBanga leNsimbi | ||||||||||||

| in | mm | I-L210(A) | I-L245(B) | I-L290(X42) | I-L320(X46) | I-L360(X52) | I-L390(X56) | I-L415(X60) | I-L450(X65) | I-L485(X70) | I-L555(X80) | |

| 8-5/8 | 219.1 | 5.0 | 5.8 | 6.7 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 |

| 7.0 | 8.1 | 9.4 | 13.9 | 15.3 | 17.3 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 11.5 | 13.4 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 9-5/8 | 244.5 | 5.0 | 5.2 | 6.0 | 10.1 | 11.1 | 12.5 | 13.6 | 14.4 | 15.6 | 16.9 | 19.3 |

| 7.0 | 7.2 | 8.4 | 14.1 | 15.6 | 17.5 | 19.0 | 20.2 | 20.7 | 20.7 | 20.7 | ||

| 10.0 | 10.3 | 12.0 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 10-3/4 | 273.1 | 5.0 | 4.6 | 5.4 | 9.0 | 10.1 | 11.2 | 12.1 | 12.9 | 14.0 | 15.1 | 17.3 |

| 7.0 | 6.5 | 7.5 | 12.6 | 13.9 | 15.7 | 17.0 | 18.1 | 19.6 | 20.7 | 20.7 | ||

| 10.0 | 9.2 | 10.8 | 18.1 | 19.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 12-3/4 | 323.9 | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.6 |

| 7.0 | 5.5 | 6.5 | 10.7 | 11.8 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.4 | ||

| 10.0 | 7.8 | 9.1 | 15.2 | 16.8 | 18.9 | 20.5 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (325.0) | 5.0 | 3.9 | 4.5 | 7.6 | 8.4 | 9.4 | 10.2 | 10.9 | 11.8 | 12.7 | 14.5 | |

| 7.0 | 5.4 | 6.3 | 10.6 | 11.7 | 13.2 | 14.3 | 15.2 | 16.5 | 17.8 | 20.3 | ||

| 10.0 | 7.8 | 9.0 | 15.2 | 16.7 | 18.8 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 13-3/8 | 339.7 | 5.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.1 | 13.9 |

| 8.0 | 5.9 | 6.9 | 11.6 | 12.8 | 14.4 | 15.6 | 16.6 | 18.0 | 19.4 | 20.7 | ||

| 12.0 | 8.9 | 10.4 | 17.4 | 19.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 14 | 355.6 | 6.0 | 4.3 | 5.0 | 8.3 | 9.2 | 10.3 | 11.2 | 11.9 | 12.9 | 13.9 | 15.9 |

| 8.0 | 5.7 | 6.6 | 11.1 | 12.2 | 13.8 | 14.9 | 15.9 | 17.2 | 18.6 | 20.7 | ||

| 12.0 | 8.5 | 9.9 | 16.6 | 18.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (377.0) | 6.0 | 4.0 | 4.7 | 7.8 | 8.6 | 9.7 | 10.6 | 11.2 | 12.2 | 13.1 | 15.0 | |

| 8.0 | 5.3 | 6.2 | 10.5 | 11.5 | 13.0 | 14.1 | 15.0 | 16.2 | 17.5 | 20.0 | ||

| 12.0 | 8.0 | 9.4 | 15.7 | 17.3 | 19.5 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 16 | 406.4 | 6.0 | 3.7 | 4.3 | 7.3 | 8.0 | 9.0 | 9.8 | 10.4 | 11.3 | 12.2 | 13.9 |

| 8.0 | 5.0 | 5.8 | 9.7 | 10.7 | 12.0 | 13.1 | 13.9 | 15.1 | 16.2 | 18.6 | ||

| 12.0 | 7.4 | 8.7 | 14.6 | 16.1 | 18.1 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (426.0) | 6.0 | 3.5 | 4.1 | 6.9 | 7.7 | 8.6 | 9.3 | 9.9 | 10.8 | 11.6 | 13.3 | |

| 8.0 | 4.7 | 5.5 | 9.3 | 10.2 | 11.5 | 12.5 | 13.2 | 14.4 | 15.5 | 17.7 | ||

| 12.0 | 7.1 | 8.3 | 13.9 | 15.3 | 17.2 | 18.7 | 19.9 | 20.7 | 20.7 | 20.7 | ||

| 18 | 457.0 | 6.0 | 3.3 | 3.9 | 6.5 | 7.1 | 8.0 | 8.7 | 9.3 | 10.0 | 10.8 | 12.4 |

| 8.0 | 4.4 | 5.1 | 8.6 | 9.5 | 10.7 | 11.6 | 12.4 | 13.4 | 14.4 | 16.5 | ||

| 12.0 | 6.6 | 7.7 | 12.9 | 14.3 | 16.1 | 17.4 | 18.5 | 20.1 | 20.7 | 20.7 | ||

| 20 | 508.0 | 6.0 | 3.0 | 3.5 | 6.2 | 6.8 | 7.7 | 8.3 | 8.8 | 9.6 | 10.3 | 11.8 |

| 8.0 | 4.0 | 4.6 | 8.2 | 9.1 | 10.2 | 11.1 | 11.8 | 12.8 | 13.7 | 15.7 | ||

| 12.0 | 6.0 | 6.9 | 12.3 | 13.6 | 15.3 | 16.6 | 17.6 | 19.1 | 20.6 | 20.7 | ||

| 16.0 | 7.9 | 9.3 | 16.4 | 18.1 | 20.4 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (529.0) | 6.0 | 2.9 | 3.3 | 5.9 | 6.5 | 7.3 | 8.0 | 8.5 | 9.2 | 9.9 | 11.3 | |

| 9.0 | 4.3 | 5.0 | 8.9 | 9.8 | 11.0 | 11.9 | 12.7 | 13.8 | 14.9 | 17.0 | ||

| 12.0 | 5.7 | 6.7 | 11.8 | 13.1 | 14.7 | 15.9 | 16.9 | 18.4 | 19.8 | 20.7 | ||

| 14.0 | 6.7 | 7.8 | 13.8 | 15.2 | 17.1 | 18.6 | 19.8 | 20.7 | 20.7 | 20.7 | ||

| 16.0 | 7.6 | 8.9 | 15.8 | 17.4 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22 | 559.0 | 6.0 | 2.7 | 3.2 | 5.6 | 6.2 | 7.0 | 7.5 | 8.0 | 8.7 | 9.4 | 10.7 |

| 9.0 | 4.1 | 4.7 | 8.4 | 9.3 | 10.4 | 11.3 | 12.0 | 13.0 | 14.1 | 16.1 | ||

| 12.0 | 5.4 | 6.3 | 11.2 | 12.4 | 13.9 | 15.1 | 16.0 | 17.4 | 18.7 | 20.7 | ||

| 14.0 | 6.3 | 7.4 | 13.1 | 14.4 | 16.2 | 17.6 | 18.7 | 20.3 | 20.7 | 20.7 | ||

| 19.1 | 8.6 | 10.0 | 17.8 | 19.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 22.2 | 10.0 | 11.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 24 | 610.0 | 6.0 | 2.5 | 2.9 | 5.1 | 5.7 | 6.4 | 6.9 | 7.3 | 8.0 | 8.6 | 9.8 |

| 9.0 | 3.7 | 4.3 | 7.7 | 8.5 | 9.6 | 10.4 | 11.0 | 12.0 | 12.9 | 14.7 | ||

| 12.0 | 5.0 | 5.8 | 10.3 | 11.3 | 12.7 | 13.8 | 14.7 | 15.9 | 17.2 | 19.7 | ||

| 14.0 | 5.8 | 6.8 | 12.0 | 13.2 | 14.9 | 16.1 | 17.1 | 18.6 | 20.0 | 20.7 | ||

| 19.1 | 7.9 | 9.1 | 16.3 | 17.9 | 20.2 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.5 | 12.0 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| (630.0) | 6.0 | 2.4 | 2.8 | 5.0 | 5.5 | 6.2 | 6.7 | 7.1 | 7.7 | 8.3 | 9.5 | |

| 9.0 | 3.6 | 4.2 | 7.5 | 8.2 | 9.3 | 10.0 | 10.7 | 11.6 | 12.5 | 14.3 | ||

| 12.0 | 4.8 | 5.6 | 9.9 | 11.0 | 12.3 | 13.4 | 14.2 | 15.4 | 16.6 | 19.0 | ||

| 16.0 | 6.4 | 7.5 | 13.3 | 14.6 | 16.5 | 17.8 | 19.0 | 20.6 | 20.7 | 20.7 | ||

| 19.1 | 7.6 | 8.9 | 15.8 | 17.5 | 19.6 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

| 25.4 | 10.2 | 11.9 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | 20.7 | ||

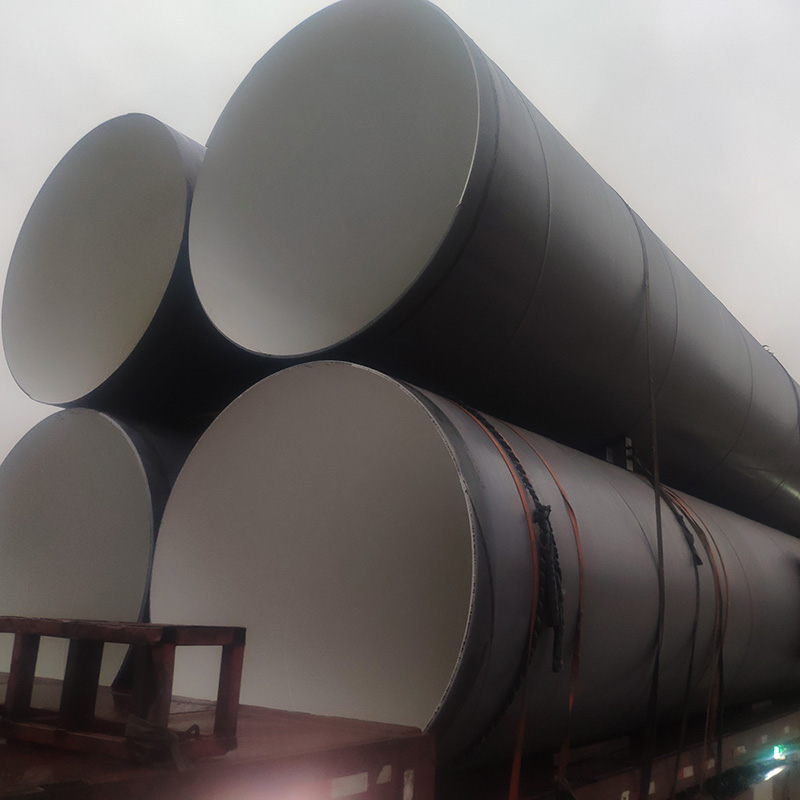

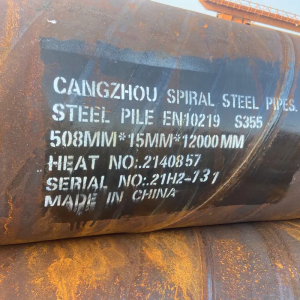

Spiral welded carbon steel pipe, ezifana S235 JR kunyeX70 SSAW umbhobho womgca, lukhetho oludumileyo kwimibhobho yamanzi angaphantsi komhlaba ngenxa yokuqina kwayo okugqwesileyo kunye nokumelana nokubola.Imibhobho yenziwa kusetyenziswa inkqubo ye-spiral welding, iqinisekisa ukuqina kunye nesakhiwo esikwaziyo ukumelana noxinzelelo kunye nemiba yokusingqongileyo ehambelana nokuthuthwa kwamanzi aphantsi komhlaba.Ukongezelela, le mibhobho yakhiwe ngentsimbi yekhabhoni ephezulu yamandla aphezulu kunye nokuphila ixesha elide, okwenza kube yinto ethembekileyo yokukhetha iinkqubo zokuhambisa amanzi ixesha elide.

Enye yeenzuzo eziphambili zokusebenzisaspiral welded carbon steel imibhobhokuba uthutho lwamanzi aphantsi komhlaba luxhathiso oluphezulu lokutya.Imibhobho engaphantsi komhlaba isoloko ivezwe kukufuma kunye nezinye izinto zokusingqongileyo, ezinokubangela ukuba izinto zemveli ezifana nekhonkrithi okanye iPVC zigruswe kwaye ziwohloke.Nangona kunjalo, iibhobho ze-carbon steel zixhathisa kakhulu kwi-corrosion, ziqinisekisa ukuba zigcina ingqibelelo yazo yesakhiwo ngokuhamba kwexesha.Oku kuxhathisa umhlwa kunciphisa kakhulu imfuno yokugcinwa kunye nokutshintshwa, ekugqibeleni konga iindleko zenkqubo yamanzi.

Ukongeza, ukomelela kunye nokuqina kombhobho wentsimbi wekhabhoni ovundiweyo kuwenza ulungele ukufakelo oluphantsi komhlaba.Le mibhobho iyakwazi ukumelana noxinzelelo lwangaphandle oluvela kumhlaba kunye nezinye izinto ezingaphantsi komhlaba, ukuqinisekisa ukuba zihlala zisebenza kwaye zisebenza ubomi babo bonke benkonzo.Ukongeza, ulwakhiwo lwayo kunye nemigangatho egudileyo yangaphakathi inciphisa umngcipheko wokuvaleka okanye ukuvuza, ukonyusa ngakumbi ukuthembeka kunye nokusebenza kakuhle kokuthuthwa kwamanzi aphantsi komhlaba.

Isishwankathelo,imibhobho yamanzi angaphantsi komhlabaziyingxenye ebalulekileyo yeziseko zanamhlanje, kwaye ukukhethwa kwezinto ezisetyenziswa kule mibhobho kubaluleke kakhulu ekusebenzeni kwabo kunye nokuphila ixesha elide.Umbhobho we-Spiral welded carbon steel, onje nge-S235 JR kunye ne-X70 SSAW umbhobho womgca, ubonelela ngeenzuzo ezininzi zokuthuthwa kwamanzi aphantsi komhlaba, kubandakanya ukuqina okuphezulu, ukumelana nokugqwala kunye namandla aphezulu.Ngokusebenzisa le mibhobho ikumgangatho ophezulu, iinkqubo zamanzi zinokuqinisekisa ukuhanjiswa kwamanzi okuthembekileyo, okusebenzayo eluntwini ngelixa kuncitshiswa imfuno yokugcinwa nokutshintshwa.