Yazisa

Kwintsimi yofakelo lwamashishini kunye nophuhliso lwezakhiwo, iipayipi zensimbi zidlala indima ebalulekileyo ekuqinisekiseni ukusebenza kakuhle kunye nokuphila ixesha elide kweenkqubo ezahlukeneyo.Phakathi kweentlobo ezahlukeneyo zemibhobho yentsimbi ekhoyo,spiral welded carbon steel imibhobhoziyaziwa ngokubanzi ngamandla azo aphezulu, ukuqina, kunye nokusebenza kakuhle kweendleko.Le mibhobho yimisebenzi yobugcisa yobunjineli, ngenxa yomgangatho ophezulu we-helical seam welding kunye neenkqubo ze-helical submerged arc welding ezisetyenziswa kwimveliso yazo.

I-Spiral Welded Carbon Steel Pipe: Ukoyisa ubunzima

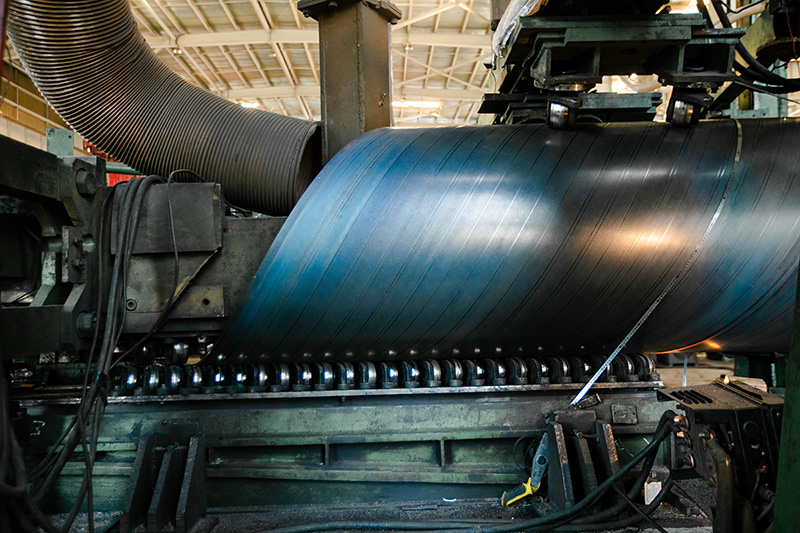

Umbhobho wentsimbi wekhabhoni odityanisiweyo wenziwa ngokwenza intsimbi yomtya ibe yimilo engqukuva engqukuva, imiphetho edityaniswe ngokudityaniswa ngokudityaniswa kwemithungo eqhubekayo.Le mibhobho yahlulwe kwimibhobho yomthungo yemveli ethe tye ngemithungo ye-helical weld entsha eyandisa ingqibelelo yesakhiwo kunye nokumelana nokugoba okanye ukuguqulwa.

Ubungcaphephe beSpiral Seam Welding

I-Spiral seam welding yinkqubo engundoqo yokwenziwa kwemibhobho yentsimbi yentsimbi ejiyileyo edityanisiweyo kwaye ibandakanya ukuwelda okuqhubekayo kwemiphetho yangaphandle nangaphakathi yomcu wentsimbi ejijelweyo.Le ndlela ye-welding engenamthungo iqinisekisa ibhondi ehambelanayo kunye neqinile kulo lonke ubude bombhobho, ukunciphisa umngcipheko wokuvuza okanye iziphene zesakhiwo.Umbhobho odityanisiweyo we-Spiral seamkwakhona ugwema imfuno yokomelezwa okongeziweyo, okwenza umbhobho ube neendleko eziphezulu ngexesha lofakelo kunye nokugcinwa.

I-Spiral Submerged Arc Welding: Ubuchwephesha obusemva koMgangatho oPhezulu

Ukuwelda kwe-arc ephantsi kwe-helical(I-HSAW) iteknoloji idlala indima ebalulekileyo ekufezekiseni imfezeko yesakhiwo esiphezulu se-spiral welded carbon steel pipes.Ngethuba le nkqubo, i-arc yenziwa ngokuqhubekayo kwaye ifakwe ngaphantsi kwe-flux layer.I-arc ke isetyenziselwa ukunyibilikisa imiphetho yomgca, ukudala ukudibanisa phakathi kwesinyithi esityhidiweyo kunye ne-substrate.Oku kudityaniswa kwenza i-weld eyomeleleyo, ekumgangatho ophezulu eneempawu ezigqwesileyo zoomatshini ezifana nokonyuka kwamandla okuqina kunye nokumelana nomhlwa.

Izinto eziluncedo zeSpiral Welded Carbon Steel Pipe

1. Amandla kunye noKuhlala ixesha elide: Iteknoloji ye-Spiral welding inika le mibhobho amandla aphezulu okubavumela ukuba bamelane noxinzelelo oluphezulu, imithwalo enzima kunye neemeko zemozulu ezimbi.

2. Ukusebenza kweendleko: Ukusebenzisa i-spiral welded carbon steel pipes kunokunciphisa kakhulu iindleko zeprojekthi ngenxa yokulula ukufakela kwaye akukho mfuneko yokomeleza okongeziweyo.

3. I-Versatility: Imibhobho ye-Spiral welded carbon steel inokuveliswa kwiidayatha ezahlukeneyo, ubude kunye nobukhulu, ibenze ilungele uluhlu olubanzi lwezicelo zoshishino.

4. I-Corrosion Resistant: Ii-welds ze-HSAW ezikumgangatho ophezulu ziqinisekisa ukuba le mibhobho inokumelana ne-corrosion egqwesileyo, yandisa ubomi babo benkonzo nakwiindawo ezinzima.

Ukuququmbela

Ubuchule bokuwelda i-spiral seam kunye ne-spiral submerged arc welding yenze utshintsho kwimveliso yemibhobho yentsimbi.Amandla aphezulu, ukuqina, kunye nokuphumelela kweendleko ze-spiral welded carbon steel pipe yenza kube yinto ekhethwayo kumashishini amaninzi.Ukukwazi kwabo ukumelana noxinzelelo, ukoyisa i-deformation kunye nokuxhathisa umhlwa kubenza babe ngumfuziselo wokugqwesa kwezobunjineli.Ngokunyuka kwemfuno yeziseko ezisebenzayo, ezithembekileyo, i-spiral welded carbon steel pipes ngokungathandabuzekiyo iya kudlala indima ebalulekileyo ekubumbeni ikamva elizinzileyo nelidibeneyo.

Ixesha lokuposa: Aug-24-2023