Yazisa

Kwicandelo lokufakelwa kwemizi-mveliso kunye nophuhliso lweziseko, iipayipi zentsimbi zidlala indima ebalulekileyo ekuqinisekiseni ukusebenza kakuhle kunye nobude bexesha leenkqubo ezahlukeneyo. Phakathi kweentlobo ezahlukeneyo zeepayipi zentsimbi ezikhoyo,imibhobho yentsimbi yekhabhoni edityanisiweyo ejikelezayoziyaziwa kakhulu ngamandla azo agqwesileyo, ukuqina, kunye nokusebenza kakuhle kweendleko. Ezi mbhobho zizinto zobuchule bobunjineli, ngenxa yeenkqubo ze-helical seam welding ezikumgangatho ophezulu kunye neenkqubo ze-helical submerged arc welding ezisetyenziswa kwimveliso yazo.

Umbhobho wentsimbi yekhabhoni odibeneyo ojikelezayo: Ukoyisa ubunzima

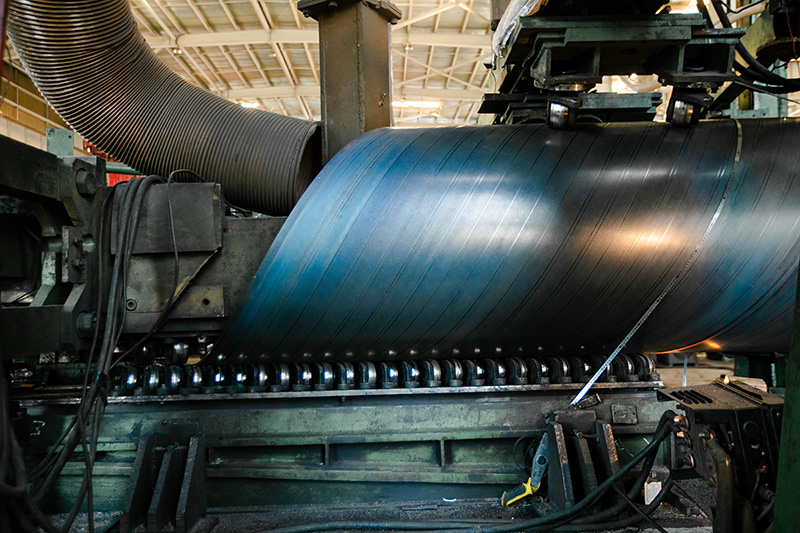

Umbhobho wentsimbi yekhabhoni odibeneyo ojikelezayo wenziwa ngokwenza intsimbi enomcu ibe yimo ye-cylindrical spiral, imiphetho yayo idityaniswe kunye nge-continuous seam welds. Le mibhobho yahlulwe kwimibhobho yendabuko ethe tye nge-helical weld seams ezintsha ezonyusa ukuthembeka kwesakhiwo kunye nokumelana nokugoba okanye ukuguquka.

Ubuchule bokuWelda ngeSpiral Seam

Ukuwelda ngomthungo ojikelezayo yinkqubo ephambili ekwenziweni kwemibhobho yentsimbi yekhabhoni edibeneyo ejikelezayo kwaye kubandakanya ukuwelda okuqhubekayo kwemiphetho yangaphandle nangaphakathi yomcu wentsimbi edibeneyo. Le ndlela yokuwelda ngomthungo iqinisekisa ukubopha okuzinzileyo nokuqinileyo kubude bombhobho, okunciphisa umngcipheko wokuvuza okanye iziphene zesakhiwo.Umthungo ojikelezayo odibeneyo wombhobhoikwathintela isidingo sokuqinisa okongeziweyo, nto leyo eyenza umbhobho ube neendleko eziphantsi xa ufakwa kwaye ugcinwa usemgangathweni.

Ukuwelda kwe-Arc efakwe kwi-Spiral Submerged: Ubuchule obuphambili kuMgangatho oPhezulu

Ukuwelda kwe-arc engaphantsi komhlaba nge-helicalItekhnoloji (HSAW) idlala indima ebalulekileyo ekufezekiseni ukuthembeka okuphezulu kwesakhiwo semibhobho yentsimbi yekhabhoni edityanisiweyo nge-spiral. Ngexesha lale nkqubo, i-arc iqhubeka iveliswa kwaye ifakwa ngaphantsi komaleko we-flux. Emva koko i-arc isetyenziselwa ukunyibilikisa imiphetho yestrip, okwenza i-fusion phakathi kwesinyithi esinyibilikisiweyo kunye ne-substrate. Le fusion yenza i-weld enamandla, esemgangathweni ophezulu eneempawu ezintle zoomatshini ezifana nokwanda kwamandla okuxinana kunye nokumelana nokugqwala.

Iingenelo zePipe yeSteel Carbon Welded Spiral

1. Amandla Nokuqina: Itekhnoloji yokuwelda ejikelezayo inika la mapayipi amandla angcono avumela ukuba akwazi ukumelana noxinzelelo oluphezulu, imithwalo enzima kunye neemeko zemozulu ezimbi kakhulu.

2. Ukusebenza kakuhle kweendleko: Ukusebenzisa imibhobho yentsimbi yekhabhoni edityanisiweyo nge-spiral kunokunciphisa kakhulu iindleko zeprojekthi ngenxa yokulula kokufakelwa kwaye akukho mfuneko yokuqinisa okongeziweyo.

3. Ukuguquguquka: Imibhobho yentsimbi yekhabhoni edityanisiweyo ejikelezayo inokwenziwa ngobubanzi obahlukeneyo, ubude kunye nobukhulu, nto leyo eyenza ukuba ifaneleke kwiintlobo ngeentlobo zezicelo zoshishino.

4. Ayikwazi Ukugqwala: Ii-weld ze-HSAW ezisemgangathweni ophezulu ziqinisekisa ukuba le mibhobho inokumelana nokugqwala okugqwesileyo, nto leyo eyandisa ubomi bayo benkonzo nakwiindawo ezinzima.

Ukuququmbela

Ubuchule bokuwelda ngomthungo ojikelezayo kunye nokuwelda ngomthungo ongaphantsi komhlaba kutshintshe imveliso yeepayipi zentsimbi. Amandla aphezulu, ukuqina, kunye nokusebenza kakuhle kwepayipi yentsimbi yekhabhoni edibeneyo kwenza ukuba ibe lolona khetho lukhethwayo kumashishini amaninzi. Amandla abo okumelana noxinzelelo, ukoyisa ukuguquka kunye nokumelana nokugqwala kubenza babe ngumzekelo wobungcali bobunjineli. Ngenxa yokwanda kwemfuno yeziseko zophuhliso ezisebenzayo nezithembekileyo, iipayipi zentsimbi yekhabhoni ezidibeneyo ngokungathandabuzekiyo ziya kudlala indima ebalulekileyo ekwakheni ikamva elizinzileyo nelidibeneyo.

Ixesha lokuthumela: Agasti-24-2023