Imibhobho yentsimbi edibeneyo ejikelezayo

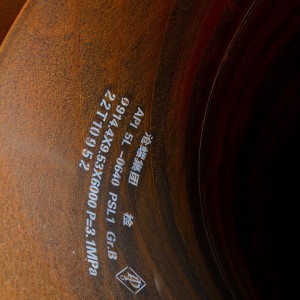

Imibhobho yentsimbi edibeneyo ejikelezayo yenzelwe ngokukodwa ukuhlangabezana neemfuno ezahlukeneyo zamashishini ahlukeneyo kwaye isetyenziswa kakhulu ekuthuthweni kweoyile negesi,inqwaba yetyhubhuulwakhiwo, iipali zeebhulorho kunye nezinye iindawo. Ulwakhiwo lwayo olwahlukileyo kunye nokusebenza kwayo okugqwesileyo kwenza ukuba ibe lolona khetho luphambili lwezixhobo zepayipi zemveli, kunye neenzuzo ezikhethekileyo eziphucula ukusebenza kwayo kunye nokusebenza kwayo kakuhle.

Enye yezona nzuzo ziphambili zeumbhobho wentsimbi odibeneyo ojikelezayoyindlela esebenza ngayo kakuhle iindleko. Xa kuthelekiswa nemibhobho yentsimbi engenamthungo, imibhobho yentsimbi edityanisiweyo itshiphu ukuvelisa ngaphandle kokubeka umgangatho esichengeni. Oku kwenza imisebenzi ibe yeyongayo ngakumbi, nto leyo eyenza ukuba ifaneleke kwiiprojekthi ezifuna imibhobho yentsimbi emininzi kwiintlobo ngeentlobo zezicelo. Ngokunciphisa iindleko, iinkampani zinokwabela izixhobo ngokufanelekileyo, nto leyo ekhokelela ekongeni okukhulu kuhlahlo-lwabiwo mali lweprojekthi iyonke.

Ipropati yoomatshini

| Ibanga loku-1 | Ibanga lesi-2 | Ibanga lesi-3 | |

| Incopho yeNzuzo okanye amandla eNzuzo, umzuzu, iMpa(PSI) | 205(30 000) | 240(35 000) | 310(45 000) |

| Amandla okutsalwa, umzuzu, i-Mpa (PSI) | 345(50 000) | 415(60 000) | 455(66 0000) |

Ukongeza, ukusebenza kakuhle kwemvelisoimibhobho yentsimbi ejikelezayoiphezulu kakhulu kuneepayipi zentsimbi ezingenamthungo. Kwipayipi engenamthungo, inkqubo yemveliso ibandakanya ukukhupha i-billet yentsimbi eqinileyo ngentonga eneembobo, nto leyo ekhokelela kwinkqubo yemveliso ecothayo neyinkimbinkimbi. Ngokwahlukileyo koko, ipayipi edibeneyo ejikelezayo inokwenziwa ngobubanzi obukhulu nobude, nto leyo ekhokelela kumaxesha okuvelisa amafutshane kunye nokusebenza kakuhle okwandisiweyo. Oku kuqinisekisa ukubonelelwa rhoqo kweepayipi ezisemgangathweni ophezulu ngexesha elifutshane, nto leyo eyenza ukuba ibe sisisombululo esithembekileyo nesigcina ixesha kwiimveliso ezahlukeneyo.

Enye inzuzo ephawulekayo yeepayipi ezidityanisiweyo ezijikelezayo kukuxhathisa kwazo kakuhle uxinzelelo lwangaphandle kunye noxinzelelo loomatshini. Ii-welds zibonelela ngokuqina okongezelelekileyo, okuvumela ezi payipi ukuba zimelane noxinzelelo oluphezulu kuneepayipi ezingenamthungo. Le propati ibaluleke kakhulu kwizicelo kwishishini leoyile negesi, apho iipayipi ziphantsi koxinzelelo olukhulu lwangaphakathi nolwangaphandle. Ngokusebenzisa iipayipi ezidityanisiweyo ezijikelezayo, iinkampani zinokuqinisekisa ukuthuthwa okukhuselekileyo nokufanelekileyo kwezi zixhobo zibalulekileyo.

Ukongeza, ubuchule bokusebenzisa umbhobho odibeneyo ojikelezayo buyenza ikwazi ukuguquguquka kwiimfuno ezahlukeneyo zokwakha. Ezi mbhobho zinokwenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile zeprojekthi, kubandakanya ububanzi obahlukeneyo, ubukhulu kunye nobude. Nokuba kukufakelwa kweepayipu okanye iipayi zebhulorho, iipayipu zentsimbi ezidibeneyo ezijikelezayo zibonelela ngezisombululo ezigqwesileyo kuzo zombini izicelo zaselunxwemeni naselunxwemeni. Ukuqina kwayo okuphezulu kuqinisekisa ukusebenza okuhlala ixesha elide, kunciphisa iindleko zokugcinwa kunye nokunciphisa isidingo sokutshintshwa kwangaphambi kwexesha.

Ngamafutshane, ipayipi edibeneyo ejikelezayo izisa utshintsho olukhulu kushishino lweepayipi zentsimbi ngokusebenza kwayo okugqwesileyo kunye neenzuzo ezibalulekileyo. Ukusebenza kwayo kakuhle kweendleko, ukusebenza kakuhle kwemveliso, ukumelana noxinzelelo kunye nokuzivumelanisa nezicelo ezininzi kwenza ukuba ibe lolona khetho luphambili ekuthuthweni kweoyile negesi, ukwakhiwa kweenqwaba zeepayipi, iipali zeebhulorho nokunye. Ngomphezulu wayo ongenamthungo kunye nemithungo edibeneyo, le mveliso intsha ibonelela ngesisombululo esithembekileyo nesihlala ixesha elide kumashishini kwihlabathi liphela. Tyala imali kwipayipi edibeneyo ejikelezayo kwaye ube namava okuqhubela phambili okusemgangathweni kubuchwepheshe beepayipi zentsimbi.