Amandla kunye nokuthembeka kweePipe zoLwakhiwo ezingenanto: Ukujonga ngokunzulu iPipe eWelded ye-Spiral Submerged Arc kunye nePipe yoMgca we-API 5L

Yazisa:

Kwihlabathi lokwakha nophuhliso lweziseko, ukukhetha izixhobo ezifanelekileyo kubalulekile.Imibhobho yesakhiwo esineenxalenye ezingenanto idlala indima ebalulekileyo ekuboneleleni ngamandla, ukuqina kunye nokuthembeka kwiiprojekthi ezahlukeneyo. Kule blog, siza kuhlola iimpawu kunye neenzuzo zeentlobo ezimbini ezibalulekileyo zepayipi yolwakhiwo: ipayipi edibeneyo ye-arc ejikelezileyo kunye nepayipi yomgca we-API 5L.

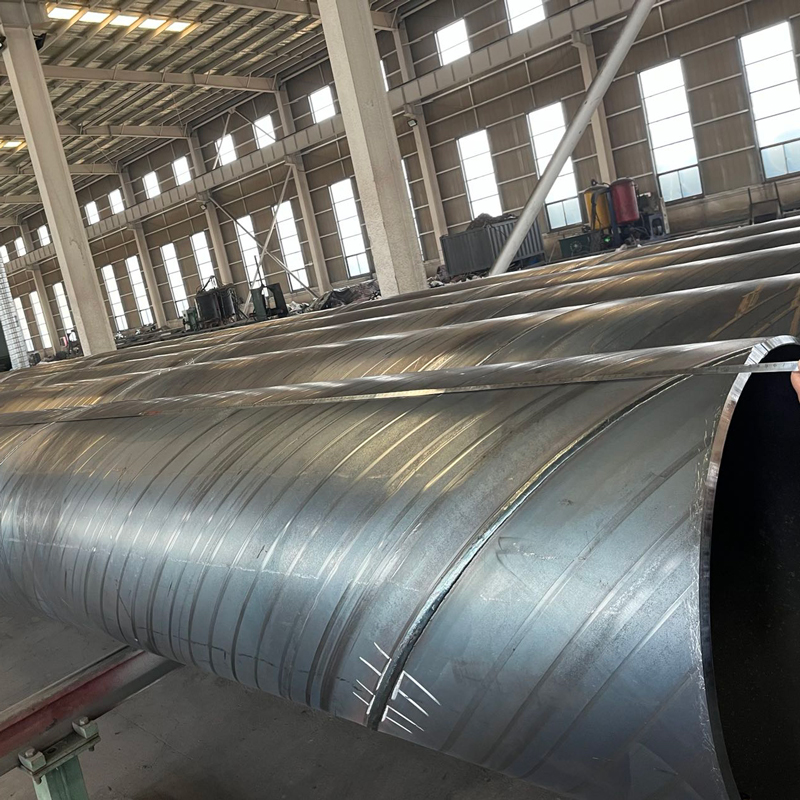

Umbhobho we-arc welding ojikeleziweyo ojikelezayo:

Umbhobho we-arc welded (SAW) ofakwe emanzini, okwaziwa ngokuba ngumbhobho we-SSAW, usetyenziswa kwiintlobo ngeentlobo zezicelo. Uphawu olukhethekileyo lweUmbhobho we-SSAW yimigca yayo ejikelezayo, enika amandla amakhulu kunye nomthamo wokuthwala umthwalo xa kuthelekiswa nezinye iintlobo zepayipi. Olu yilo lukhethekileyo lunceda ukusasaza uxinzelelo ngokulinganayo kuyo yonke ipayipi, nto leyo eyenza ukuba ifaneleke kwiiprojekthi ezifuna ukuqina kwesakhiwo.

Iimpawu zoomatshini zombhobho we-SSAW

| inqanaba lesinyithi | amandla amancinci okuvelisa | ubuncinci bokuqina koxinzelelo | Ubuncinane bobude |

| B | 245 | 415 | 23 |

| X42 | 290 | 415 | 23 |

| X46 | 320 | 435 | 22 |

| X52 | 360 | 460 | 21 |

| X56 | 390 | 490 | 19 |

| X60 | 415 | 520 | 18 |

| X65 | 450 | 535 | 18 |

| X70 | 485 | 570 | 17 |

Ukwakheka kweekhemikhali kwimibhobho ye-SSAW

| inqanaba lesinyithi | C | Mn | P | S | V+Nb+Ti |

| Ubuninzi % | Ubuninzi % | Ubuninzi % | Ubuninzi % | Ubuninzi % | |

| B | 0.26 | 1.2 | 0.03 | 0.03 | 0.15 |

| X42 | 0.26 | 1.3 | 0.03 | 0.03 | 0.15 |

| X46 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X52 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X56 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X60 | 0.26 | 1.4 | 0.03 | 0.03 | 0.15 |

| X65 | 0.26 | 1.45 | 0.03 | 0.03 | 0.15 |

| X70 | 0.26 | 1.65 | 0.03 | 0.03 | 0.15 |

Ukunyamezelana kweJiyometri kwemibhobho ye-SSAW

| Ukunyamezelana kwejometri | ||||||||||

| ububanzi obungaphandle | Ubukhulu bodonga | ukuthe tye | ukungaguquguquki | ubunzima | Ukuphakama okuphezulu kwe-weld bead | |||||

| D | T | |||||||||

| ≤1422mm | >1422mm | <15mm | ≥15mm | isiphelo sombhobho 1.5m | ubude obuphelele | umzimba wombhobho | isiphelo sombhobho | T≤13mm | T >13mm | |

| ± 0.5% | njengoko kuvunyelwene | ± 10% | ± 1.5mm | 3.2mm | 0.2% L | 0.020D | 0.015D | '+10% | 3.5mm | 4.8mm |

Uvavanyo lwe-Hydrostatic

Umbhobho kufuneka umelane novavanyo lwe-hydrostatic ngaphandle kokuvuza ngomthungo we-weld okanye umzimba wombhobho

Iijoyinti akufuneki zivavanywe ngamanzi, ukuba nje iinxalenye zombhobho ezisetyenzisiweyo ekuphawuleni iijoyinti zivavanywe ngempumelelo ngamanzi ngaphambi kokuba kusebenze ukujoyina.

Ukulandeleka:

Kwipayipi yePSL 1, umenzi kufuneka amisele aze alandele iinkqubo ezibhaliweyo zokugcina:

Ubume bobushushu de kube kwenziwe uvavanyo ngalunye oluhambelanayo lwe-chmical kwaye kuboniswe ukuhambelana neemfuno ezichaziweyo

Ubungqina beyunithi yovavanyo de kube kwenziwe uvavanyo ngalunye oluhambelanayo loomatshini kwaye kuboniswe ukuhambelana neemfuno ezichaziweyo

Kwipayipi yePSL 2, umenzi kufuneka amisele aze alandele iinkqubo ezibhaliweyo zokugcina ubume bobushushu kunye nobume beyunithi yovavanyo kuloo payipi. Ezi nkqubo kufuneka zibonelele ngeendlela zokulandelela nabuphi na ubude bombhobho kwiyunithi yovavanyo efanelekileyo kunye neziphumo zovavanyo lweekhemikhali ezinxulumene noko.

Enye yezona nzuzo ziphambili zombhobho we-SSAW kukuguquguquka kwawo ekwenzeni. Ezi mbhobho zinokwenziwa ngobukhulu obahlukeneyo, ububanzi kunye nobukhulu kwaye zinokwenziwa ngokwezifiso ukuhlangabezana neemfuno zeprojekthi ethile. Ukongeza, iimbhobho ezifakwe kwi-spiral submerged arc welded zihlala zenziwe ngentsimbi ekumgangatho ophezulu, nto leyo eyenza ukuba zingagqwali kwaye ziqinisekise ubomi benkonzo obude.

Umbhobho woMgca we-API 5L:

Umbhobho womgca we-API 5Lngumbhobho wolwakhiwo osetyenziswa kakhulu onendawo engenanto ohlangabezana nemigangatho ye-American Petroleum Institute (API). Le mibhobho yenzelwe ukuthutha ulwelo, olufana neoyile kunye negesi yendalo, kumgama omde. Umbhobho womgca we-API 5L waziwa ngamandla awo aphezulu, ukuqina kunye nokumelana neemeko ezimandundu zokusingqongileyo.

Inkqubo yokuvelisa umbhobho womgca we-API 5L ibandakanya amanyathelo angqongqo okulawula umgangatho ukuqinisekisa ukuthembeka kwawo. Le mibhobho yenziwe ngentsimbi yekhabhoni kwaye ineempawu ezintle zoomatshini. Ukubambelela ngokuqinileyo kwimigangatho ye-API kuqinisekisa ukuba le mibhobho inokumelana noxinzelelo oluphezulu kunye notshintsho lobushushu, nto leyo eyenza ifaneleke kwizicelo ezibalulekileyo kwishishini leoyile negesi.

Iingenelo ezidibeneyo:

Xa zidityanisiwe ipayipi edibeneyo ye-arc engaphantsi komhlaba kunye nombhobho womgca we-API 5L, zibonelela ngokuthembeka nokuthembeka kwesakhiwo ngendlela engenakuthelekiswa nanto. Ii-spiral seams zepayipi ye-SSAW ezidityaniswe namandla kunye nokuqina kombhobho womgca we-API 5L zenza inkqubo yokuxhasa isakhiwo eqinileyo.

Ukongeza kwiingenelo zazo, ukuhambelana kombhobho ofakwe kwi-spiral arc welded kunye nombhobho womgca we-API 5L kwandisa ukusebenza kakuhle kweeprojekthi zemibhobho. Ukuguquguquka kombhobho we-SSAW kuvumela ukunxibelelana okulula nombhobho womgca we-API 5L, okuqinisekisa ukuhamba kakuhle kolwelo ngaphakathi kwenethiwekhi yemibhobho.

Ukuququmbela:

Iipayipi ezakhiweyo ezinemiqolo zibaluleke kakhulu xa kusakhiwa iziseko zophuhliso eziqinileyo. Ukusetyenziswa okudibeneyo kwepayipi ye-SSAW kunye nepayipi yomgca we-API 5L kubonelela ngesisombululo esinamandla esinika amandla, ukuqina kunye nokuthembeka kwiiprojekthi ezahlukeneyo. Nokuba zixhasa iziseko zezakhiwo ezinde okanye zithutha ulwelo olubalulekileyo kumgama omde, ezi payipi zidlala indima ebalulekileyo ekuqinisekiseni ukuba iziseko zethu zihlala ixesha elide kwaye zizinzile. Ngokusebenzisa amandla epayipi edibeneyo ye-spiral submerged arc kunye nokuthembeka kwepayipi yomgca we-API 5L, iinjineli zinokukha isiseko esiqinileyo sekamva elingcono.