Iipayipi zokuQokelela eziWelded ezinobubanzi obukhulu

Kwiminyaka yakutshanje, imfuno yokufaka imibhobho yentsimbi kwiinkampani ezahlukeneyo ikhule kakhulu. Ngokukhula ngokukhawuleza kophuhliso lolwakhiwo kunye neziseko zophuhliso, ububanzi be umbhobho wokufaka iintsikaiyanda ngokukhula. Ke ngoko, imfuneko yeepayipu zentsimbi ezinkulu ezidityanisiweyo ezikumgangatho ophezulu ezidityanisiweyo nge-spiral ekumgangatho ophezulu iba yinto ebalulekileyo.

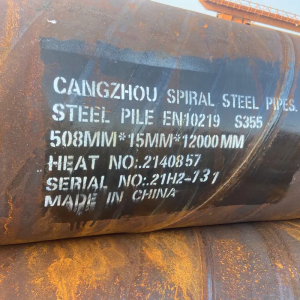

Kwinkampani yethu, siyibonile le mfuno ikhulayo saza saphuhlisa isisombululo esiphambili sokuhlangabezana neemfuno zemarike - iipayipu zethu zentsimbi ezinkulu ezinobubanzi. Ezi payipu zineepayipu zenzelwe ukubonelela ngomthamo oyintloko wokuthwala umthwalo weendawo zokugcina amanzi anzulu, nto leyo eyenza zibe yinxalenye ebalulekileyo yayo nayiphi na iprojekthi yokwakha ulwandle.

| Umgangatho | Ibanga lentsimbi | Ukwakheka kweekhemikhali | Iipropati zokuxinana | Uvavanyo lweCharpy Impact kunye novavanyo lweDrop Weight Tear | ||||||||||||||

| C | Si | Mn | P | S | V | Nb | Ti | I-CEV4)(%) | Amandla okukhupha i-Rt0.5 Mpa | Amandla okuThanda eRm Mpa | Rt0.5/ Rm | (L0=5.65 √ S0)Ukwandiswa kwe-A% | ||||||

| ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | ubuninzi | Okunye | ubuninzi | umzuzu | ubuninzi | umzuzu | ubuninzi | ubuninzi | umzuzu | |||

| L245MB | 0.22 | 0.45 | 1.2 | 0.025 | 0.15 | 0.05 | 0.05 | 0.04 | 1) | 0.4 | 245 | 450 | 415 | 760 | 0.93 | 22 | Uvavanyo lwempembelelo yeCharpy: Amandla okufunxa impembelelo yomzimba wombhobho kunye nomthungo we-weld kufuneka avavanywe njengoko kufuneka kumgangatho wokuqala. Ukuze ufumane iinkcukacha, jonga umgangatho wokuqala. Uvavanyo lokukrazula ubunzima bokulahla: Indawo yokucheba ekhethiweyo | |

| GB/T9711-2011(PSL2) | I-L290MB | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 1) | 0.4 | 290 | 495 | 415 | 21 | |||

| I-L320MB | 0.22 | 0.45 | 1.3 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 1) | 0.41 | 320 | 500 | 430 | 21 | ||||

| I-L360MB | 0.22 | 0.45 | 1.4 | 0.025 | 0.015 | 1) | 0.41 | 360 | 530 | 460 | 20 | |||||||

| I-L390MB | 0.22 | 0.45 | 1.4 | 0.025 | 0.15 | 1) | 0.41 | 390 | 545 | 490 | 20 | |||||||

| I-L415MB | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | 1)2)3 | 0.42 | 415 | 565 | 520 | 18 | |||||||

| I-L450MB | 0.12 | 0.45 | 1.6 | 0.025 | 0.015 | 1)2)3 | 0.43 | 450 | 600 | 535 | 18 | |||||||

| I-L485MB | 0.12 | 0.45 | 1.7 | 0.025 | 0.015 | 1)2)3 | 0.43 | 485 | 635 | 570 | 18 | |||||||

| I-L555MB | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | 1)2)3 | Ingxoxo | 555 | 705 | 625 | 825 | 0.95 | 18 | |||||

| Phawula: | ||||||||||||||||||

| 1)0.015 ≤ Altot < 0.060;N ≤ 0.012;AI—N ≥ 2—1;Cu ≤ 0.25;Ni ≤ 0.30;Cr ≤ 0.30;Mo ≤ 0.10; | ||||||||||||||||||

| 2(V+Nb+Ti ≤ 0.015% | ||||||||||||||||||

| 3)Kuzo zonke iiklasi zentsimbi, iMo inokuba ≤ 0.35%, phantsi kwesivumelwano. | ||||||||||||||||||

| Mn Cr+Mo+V I-Cu+Ni4)CEV=C+ 6 + 5 + 5 | ||||||||||||||||||

Zethuiipayipu zentsimbi eziwelsiweyo ezijikelezayoZenziwa kusetyenziswa ubuchwepheshe bamva nje ukumelana neemeko ezinzima. Nokuba kukwakhiwa kweebhulorho, ukwakhiwa kwendlela, izakhiwo eziphakamileyo okanye naluphi na olunye uhlobo lwesicelo olufuna isiseko esithembekileyo, iipayipi zethu zokufaka iintsika zifanelekile.

Okwahlukanisa iipayipi zethu zokufaka iintsika ngumgangatho wazo ogqwesileyo kunye nokuqina kwazo. Siyaqonda ukubaluleka kwesiseko esomeleleyo nesizinzileyo, yiyo loo nto senza konke okusemandleni ethu ukuqinisekisa ukuba iipali zethu zentsimbi ezinkulu ezinobubanzi zihlangabezana nemigangatho ephezulu yokugqwesa. Ngokwakhiwa kwazo okuqinileyo kunye netekhnoloji yokuwelda ephucukileyo, iipali zethu zokufaka iintsika zakhiwe ukuze zihlale ixesha elide, zikunika uxolo lwengqondo ukwazi ukuba iprojekthi yakho ixhaswa bubuchwepheshe obubalaseleyo kushishino.

Ukongeza, iipayipi zethu zokugquma ziyafumaneka ngobukhulu obahlukeneyo ukuhlangabezana neemfuno ezithile zeprojekthi yakho. Nokuba ufuna iipayipi ezinkulu ezidityanisiweyo okanye ezincinci, singakunika isisombululo esifanelekileyo kwiimfuno zakho.

Ukongeza, siyazingca kakhulu ngokuzinikela kwethu ekuzinzeni kwendalo. Iipayipu zethu zentsimbi ezidityanisiweyo nge-spiral zenziwe ngeenkqubo ezinobuhlobo nokusingqongileyo, ukuqinisekisa ukuba azifikeleli nje kuphela kwimigangatho ephezulu yomgangatho kodwa zikwathobela nemigaqo engqongqo yokusingqongileyo. Oku kuthetha ukuba xa ukhetha iipayipu zethu zokufaka iintsika, awutyali nje kuphela kwisisombululo sesiseko esithembekileyo nesihlala ixesha elide, kodwa ukwanegalelo kwikamva eliluhlaza nelizinzileyo.

Ngamafutshane, iipayipi zethu zokufaka iipayipi, kuquka neepayipi zentsimbi ezifakwe i-spiral welded, zingumzekelo wokugqwesa kushishino. Ngenxa yomgangatho wazo ongenakuthelekiswa nanto, ukuqina kwazo kunye nokuzinza kokusingqongileyo, zilukhetho olufanelekileyo kuyo nayiphi na iprojekthi efuna isiseko esithembekileyo. Ke ngoko, xa kufikwa ekuhlangabezaneni neemfuno zakho zeepayipi zokufaka iipayipi, inkampani yethu lolona khetho lwakho lubalaseleyo. Sizimisele ukukunika izisombululo ezilungileyo kuzo zonke iimfuno zakho ezisisiseko.