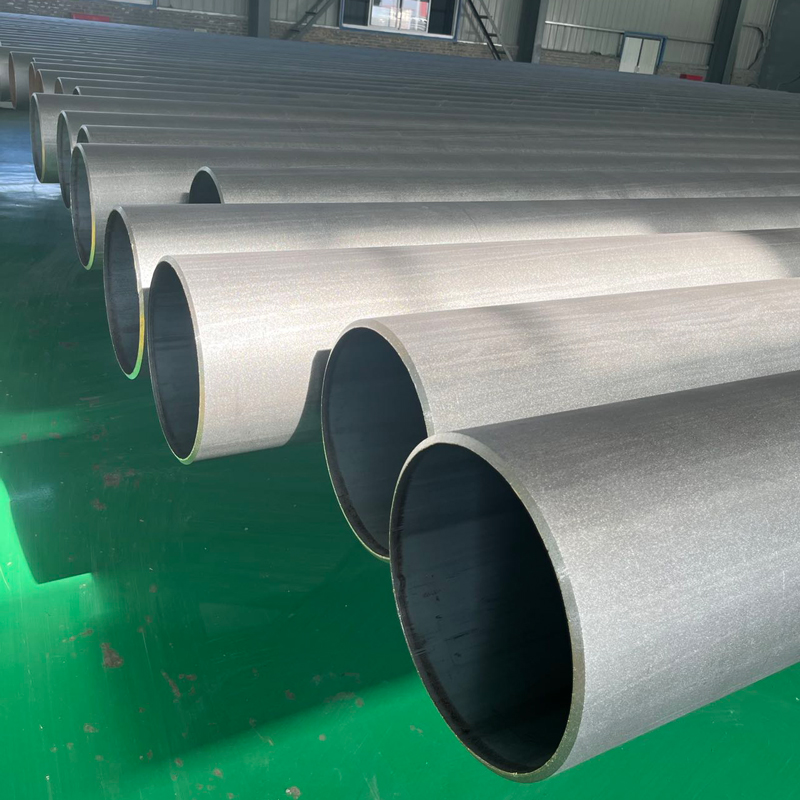

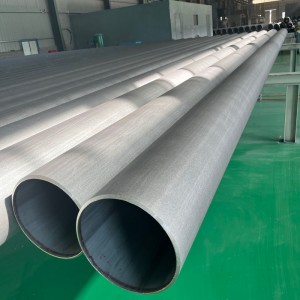

Iingubo ze-Epoxy eziDityanisiweyo ze-Fusion-Bonded Awwa C213 ezisemgangathweni

Iimpawu ezibonakalayo zezinto ze-epoxy powder

Ubunzima obuthile kwi-23℃: ubuncinci yi-1.2 kwaye ubuninzi yi-1.8

Uhlalutyo lwesihluzo: ubuninzi be-2.0

Ixesha lejeli kwi-200 ℃: ngaphantsi kwe-120s

Ukucoca ngokuqhumisa okurhabaxa

Imiphezulu yentsimbi engenanto kufuneka icocwe ngokurhabaxa ngokuhambelana ne-SSPC-SP10/NACE No. 2 ngaphandle kokuba kuchazwe ngenye indlela ngumthengi. Ipateni ye-blast anchor okanye ubunzulu beprofayili buya kuba yi-1.5 mil ukuya kwi-4.0 mil (38 µm ukuya kwi-102 µm) elinganiswe ngokuhambelana ne-ASTM D4417.

Ukufudumeza

Umbhobho ocociweyo mawufudunyezwe kubushushu obungaphantsi kwama-260℃, umthombo wobushushu awufanele ungcolise umphezulu wombhobho.

Ubukhulu

Umgubo wokugquma kufuneka usetyenziswe kumbhobho oshushubeziweyo ngobukhulu obufanayo obungaphantsi kwe-12 mils (305μm) ngaphandle okanye ngaphakathi. Ubukhulu obukhulu abuyi kudlula i-16 mils (406μm) ngaphandle kokuba kucetyiswe ngumvelisi okanye kuchazwe ngumthengi.

Uvavanyo lokusebenza lwe-epoxy olukhethekayo

Umthengi angachaza uvavanyo olongezelelweyo ukuze aqinisekise ukusebenza kwe-epoxy. Ezi nkqubo zilandelayo zovavanyo, zonke eziya kwenziwa kwiiringi zovavanyo lombhobho wokuvelisa, zingachazwa:

1. Ukuvuleka kweendawo ezinqamlezileyo.

2. Iimbobo zojongano.

3. Uhlalutyo lobushushu (i-DSC).

4. Uxinzelelo oluhlala luhleli (ukugoba).

5. Ukumanzisa emanzini.

6. Impembelelo.

7. Uvavanyo lokuqhekeka kweCathodic.