Iingenelo kunye nosetyenziso lweeSpiral Welded Tubes kwiShishini lanamhlanje

Yazisa:

Kwimimandla yobunjineli nokwakha ekhula rhoqo, ukusetyenziswaumbhobho odibeneyo ojikelezayoithandwa kakhulu. Ezi pipe ziguquguqukayo nezihlala ixesha elide ziye zangena kumashishini ahlukeneyo, nto leyo ebonisa ukuba zisisombululo esiphucukileyo kwiintlobo ngeentlobo zezicelo. Kule posi yebhlog, siza kujonga ngokusondeleyo iingenelo ezimangalisayo ezinikezelwa ziipipe ezidityanisiweyo ezijikelezayo kwaye sihlolisise usetyenziso lwazo olwahlukeneyo kumashishini anamhlanje.

Ipropati yoomatshini

| inqanaba lesinyithi | amandla amancinci okuvelisa | Tensile strength | Ubuncinane bobude | Amandla amancinci empembelelo | ||||

| Ubukhulu obuchaziweyo | Ubukhulu obuchaziweyo | Ubukhulu obuchaziweyo | kubushushu bovavanyo lwe | |||||

| 16 | >16≤40 | <3 | ≥3≤40 | ≤40 | -20℃ | 0℃ | 20℃ | |

| S235JRH | 235 | 225 | 360-510 | 360-510 | 24 | - | - | 27 |

| S275J0H | 275 | 265 | 430-580 | 410-560 | 20 | - | 27 | - |

| S275J2H | 27 | - | - | |||||

| S355J0H | 365 | 345 | 510-680 | 470-630 | 20 | - | 27 | - |

| S355J2H | 27 | - | - | |||||

| S355K2H | 40 | - | - | |||||

1. Yintoni umbhobho odibeneyo ojikelezayo?

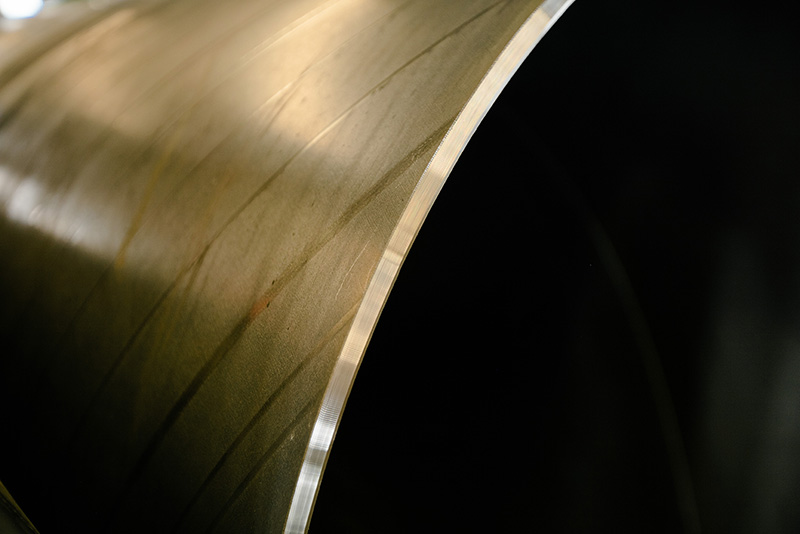

Ityhubhu edibeneyo ejikelezayo, njengoko igama lisitsho, iveliswa ngokuqengqa umcu wentsimbi rhoqo kwaye uyidibanise ubude bayo ukuze yenze umbhobho ojikelezayo. Le ndlela yokwenza iqinisekisa amandla aphezulu kunye nokuthembeka, okwenza ezi tyhubhu zilungele ukusetyenziswa okungafunekiyo.

2. Iingenelo zombhobho odibeneyo ojikelezayo:

2.1 Amandla nokuqina:

Inkqubo yokuwelda ejikelezayo ngokwemvelo inika umbhobho amandla angaphezulu. Oku kubavumela ukuba bamelane noxinzelelo lwangaphakathi oluphezulu, imithwalo enzima kunye nobushushu obugqithisileyo. Ke ngoko, zisetyenziswa kakhulu kumashishini apho ukuqina kwesakhiwo kubaluleke kakhulu.

2.2 Ukumelana nokugqwala:

Umbhobho odibeneyo ojikelezayo ufumaneka ngezinto ezahlukeneyo, kuquka intsimbi engatyiwayo kunye nee-alloys ezimelana nokugqwala. Ukumelana kwazo nokugqwala kuzenza zilungele ukusetyenziswa kumashishini eekhemikhali, ioyile kunye negesi, kunye nonyango lwamanzi. Zandisa ubomi benkonzo kwaye zinciphisa umngcipheko wokuvuza kunye nexesha lokungasebenzi.

2.3 Ukusebenza kakuhle kweendleko:

Ukuwelda okujikelezayo kunika iingenelo zeendleko xa kuthelekiswa neendlela zemveli zokwenza iipayipi. Oku kungenxa yokuncipha kwexesha lokuvelisa kunye nokuncipha kokusetyenziswa kwezinto. Ukongeza, ukwakheka okuhle kweepayipi ezijikelezileyo ezijikelezileyo kuvumela uyilo olwenziwe ngokwezifiso kunye nezisombululo ezenziwe ngokwezifiso, ukuphucula iindleko ngokunciphisa inkunkuma kunye nokunciphisa isidingo sezixhobo ezongezelelweyo.

3. Ukusetyenziswa kombhobho odibeneyo ojikelezayo:

3.1 Izakhiwo kunye neZiseko zoPhuhliso:

Iipayipi ezifakwe i-spiral weld zisetyenziswa kakhulu kushishino lokwakha, ingakumbi kwiiprojekthi ezinkulu. Zisetyenziswa kakhulu ekwenzeni izakhiwo zeekholamu, imiqadi kunye neenqwaba. Ngenxa yokuba zinamandla amakhulu, zinokumelana nemithwalo enzima kwaye zimelane namandla asecaleni, nto leyo eyenza ukuba zifaneleke ukwakhiwa kweebhulorho, izakhiwo eziphakamileyo kunye neziseko ezinzulu.

3.2 Ishishini leoyile negesi:

Kwicandelo leoyile negesi, iipayipi ezifakwe i-spiral weld zisetyenziswa kakhulu ekuthuthweni kweemveliso zepetroli, igesi yendalo kunye nezinye izinto eziphumayo. Amandla ombhobho okumelana neendawo ezinoxinzelelo oluphezulu, ukufaneleka kokusetyenziswa kolwandle olunzulu kunye nokumelana nokugqwala kwenza ukuba ibe lolona khetho luphambili kwiipayipi, ii-risers kunye nokufakelwa kolwandle.

3.3 Ubunjineli boomatshini:

Iipayipi ezihlanganisiweyo ezijikelezayo zisetyenziswa kwiindlela ezahlukeneyo zobunjineli boomatshini kwaye zibalasele ngokuqina kwazo kunye nokuguquguquka kwazo. Zisetyenziswa ekwenziweni koomatshini, iinkqubo zothutho kunye nezinto zokwakha. Ukongeza, zidlala indima ebalulekileyo kwishishini leemoto, zibonelela ngenkxaso yesakhiwo ngokubanzi kwisakhelo kunye nenkqubo yokukhupha umoya.

Ukuququmbela:

Njengoko ishishini liqhubeka likhula, imfuneko yezisombululo eziqinileyo, ezihlala ixesha elide nezingabizi kakhulu iyaqhubeka ikhula. Iipayipi ezidityanisiweyo ezijikelezayo ziyahlangabezana ngempumelelo nezi mfuno kwaye ziba yimpahla ebalulekileyo kwiinkalo ezininzi. Amandla azo aphezulu, ukumelana nokugqwala kunye nokusebenza kakuhle kweendleko kuqinisa ngakumbi isikhundla sazo njengokhetho lokuqala kwiintlobo ngeentlobo zezicelo zobunjineli. Njengoko siqhubeka phambili, kuyacaca ukuba iipayipi ezidityanisiweyo ezijikelezayo ziya kuqhubeka nokubumba ikamva leshishini lanamhlanje.